We kick off by checking the engine’s health with a compression test to see how it’s doing. After that, we give the engine a thorough cleaning to get rid of the stubborn oil and dirt buildup.

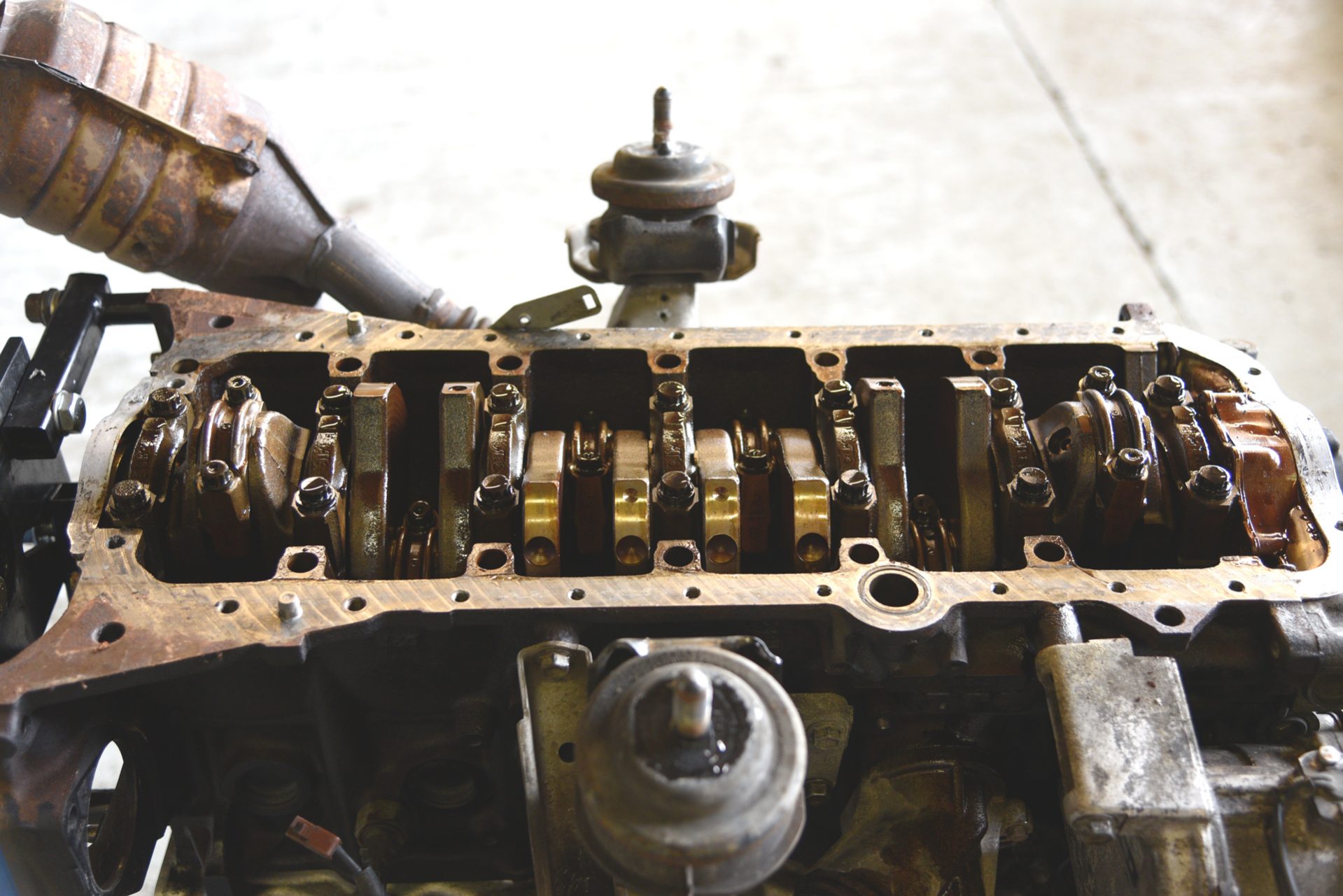

Next up we take the engine apart, carefully inspecting each part. We check the specifications of all the removed components to determine if they can be reused. This step ensures durability and helps avoid issues with underperforming engines and unexpected costs.

Now, with a clear understanding of what needs to be done, we’ll identify the parts to be ordered and determine if any additional work or machining is necessary. Once all the required components are in and everything is set, we’ll begin assembling your new power unit.

If needed or desired, we offer services such as balancing and polishing the crankshaft, pistons, and rods, as well as bore and hone the block, and more. We’re here to cater to your specific requests, and we’ll keep you informed in advance about any potential weaknesses or requirements of the engine. Our thorough documentation includes a comprehensive build sheet, and if you’d like, we can provide picture documentation as well.