We are specialized in Toyota and Lexus. This means, that JZ, UZ, S model engine blocks are among the engines we mostly work on. These engines have gained a huge following and are also a ‘no brainpain’ choice when it comes to engine swaps and high horsepower applications due to their race heritage and pure strength from the factory.

Alignment

At CBS Racing we also do complete engine swaps, and top to bottom engine builds. With a dedicated engine room and a clinical eye for detail, we strive to build every engine to the highest of standards.

Needs and budgets vary from car to car, and from owner to owner, but we do our best to accommodate the needs and financial reach of our customers.

OUR SPECIALTIES

THE PROCESS

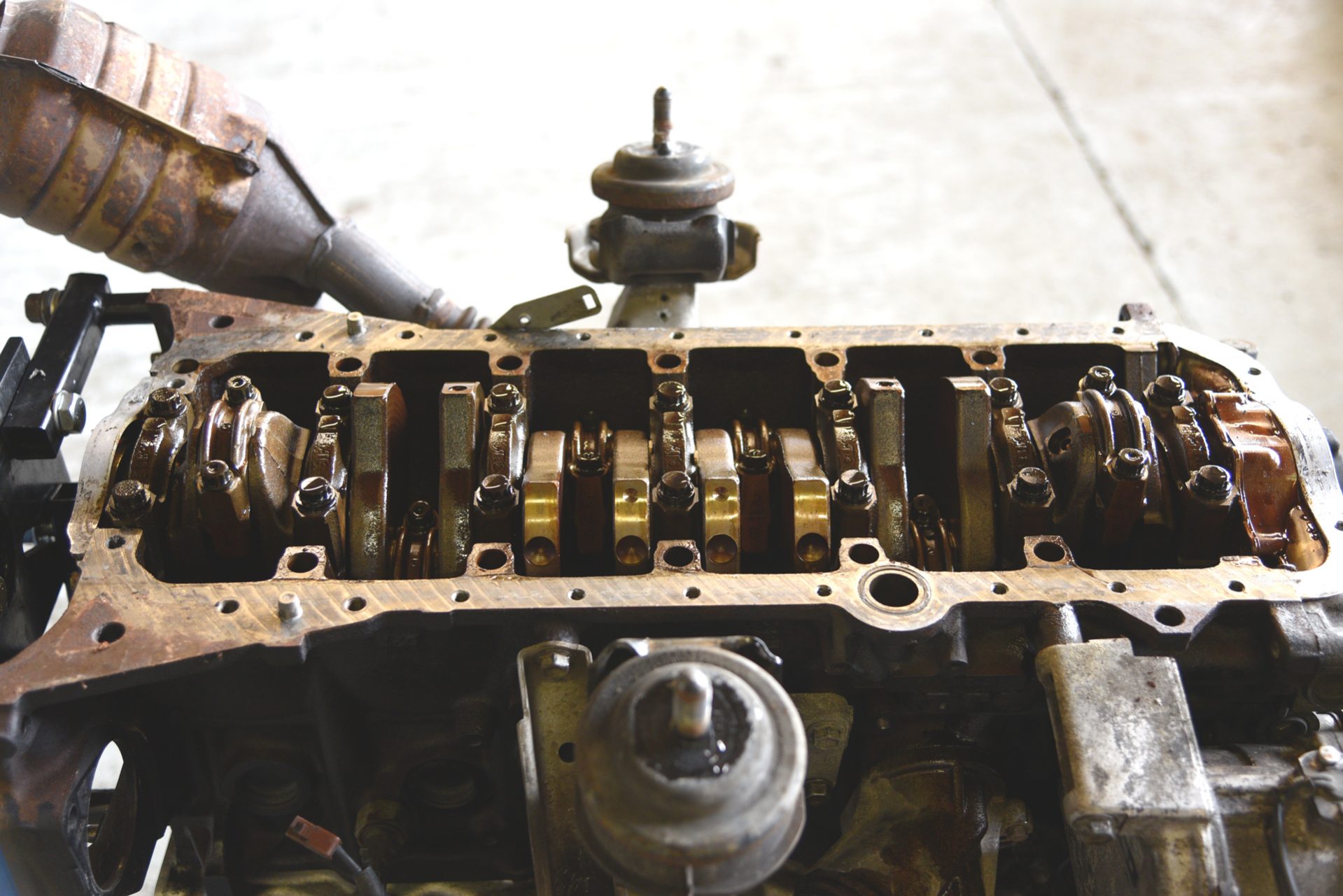

Our process starts out with a health check of the engine with a compression test to determine the health of the engine. We then clean and wash the engine as complete as possible in order to remove the worst of the “baked-on” oil and dirt.

Breakdown of the engine comes next. Examining and checking specifications on all parts removed with the intention of reuse – again ensuring durability and avoiding underperforming engines and unexpected costs.

At this point, we’ll know exactly what we’ll need to do. What parts need to be ordered and/or if any additional work or machining is required. When all parts are in and everything is ready, we will start on building your new power plant up.

If necessary or wanted, we will balance and polish the crankshaft, weight the pistons, hone the block, grind piston rings… We do it all on request, and we will inform you beforehand to the best of our ability of the weak points and needs of the engine. Everything gets documented and you get a comprehensive build sheet and picture documentation.