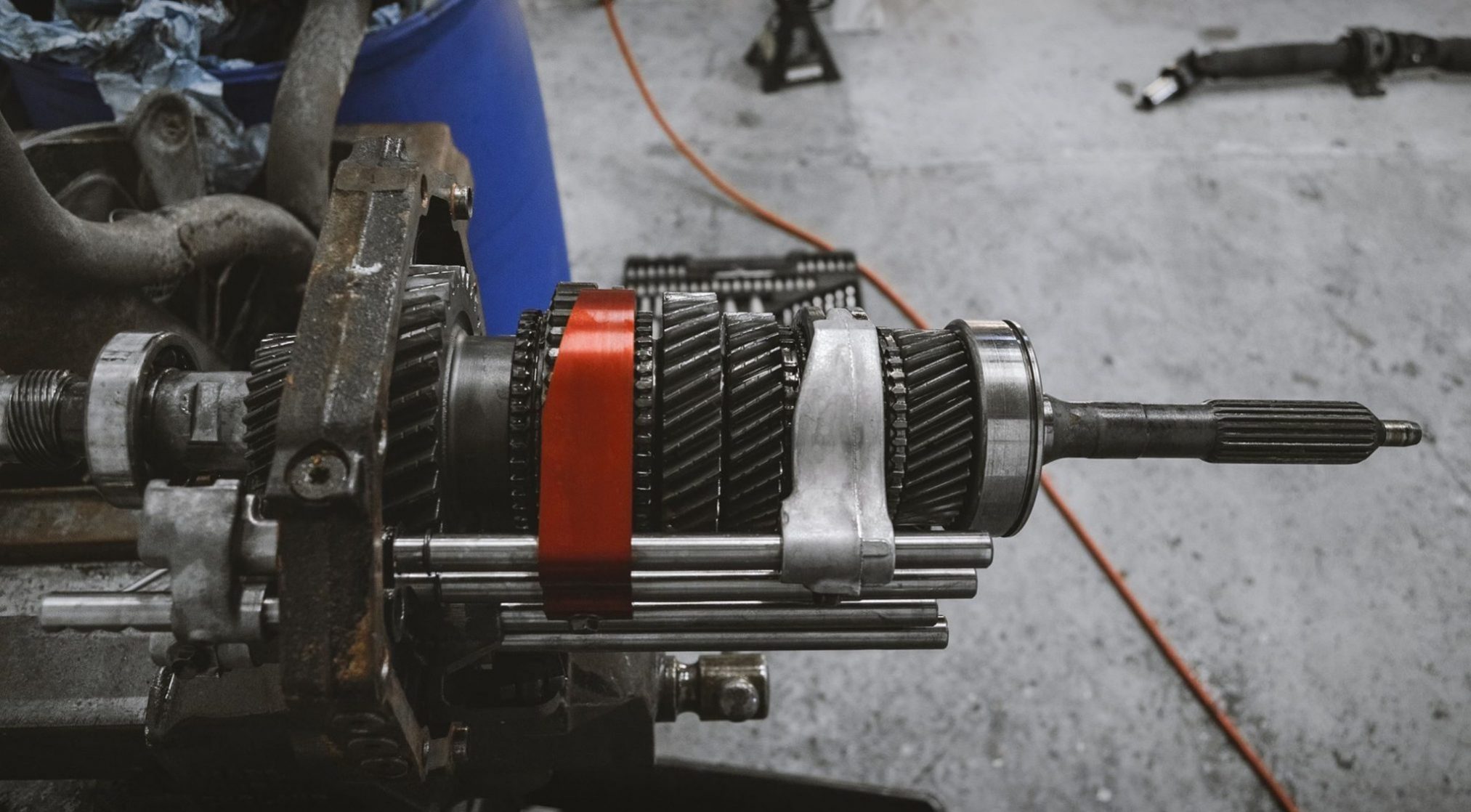

The gearbox rebuild or upgrade process kicks off in our dedicated cleanroom, where we meticulously disassemble the housings until the gears, bearings, and synchros are exposed.

Utilizing original data, we measure and assess the current parts to establish a solid baseline for durability. This approach helps identify areas for improvement and prevents unexpected costs down the road.

At this stage, we’ll have a clear understanding of the worn parts and necessary actions. We prioritize transparency and will update the customer in advance about the condition of the gearbox internals and the necessary steps to achieve optimal performance.

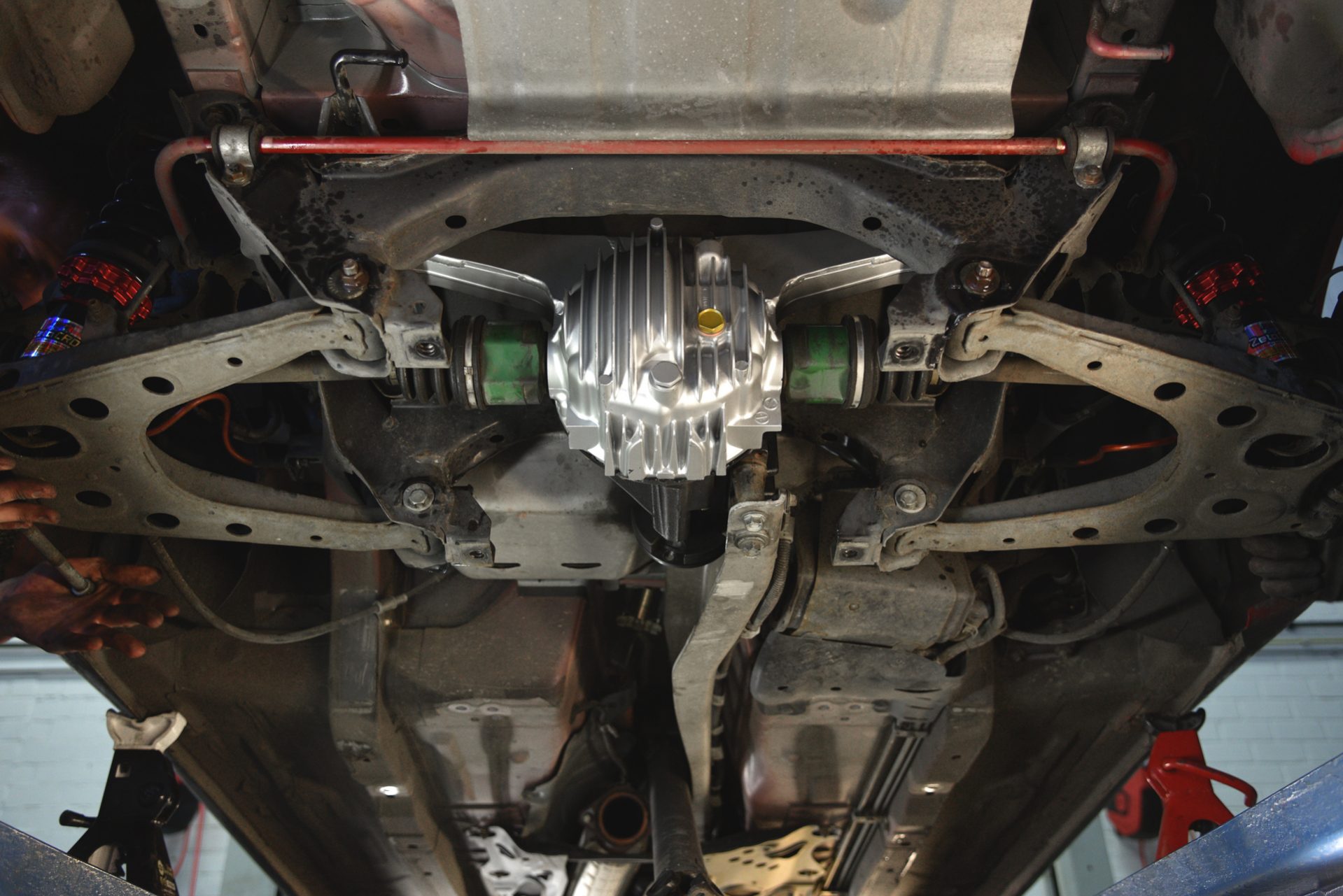

Following this assessment, we initiate the rebuild based on the customer’s preferences. Throughout the process, we maintain a high level of cleanliness and strictly adhere to the manufacturers’ specifications to guarantee precision and quality at every step.

Our favorite gearboxes include Toyota’s V160, R154 and E153 – they’re very strong powerhouses from the factory and are seen performing perfectly at high horsepower applications.